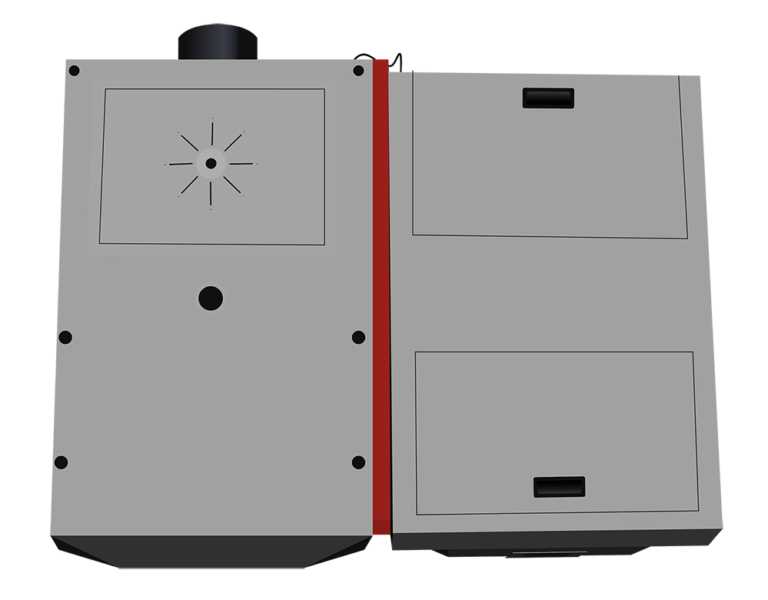

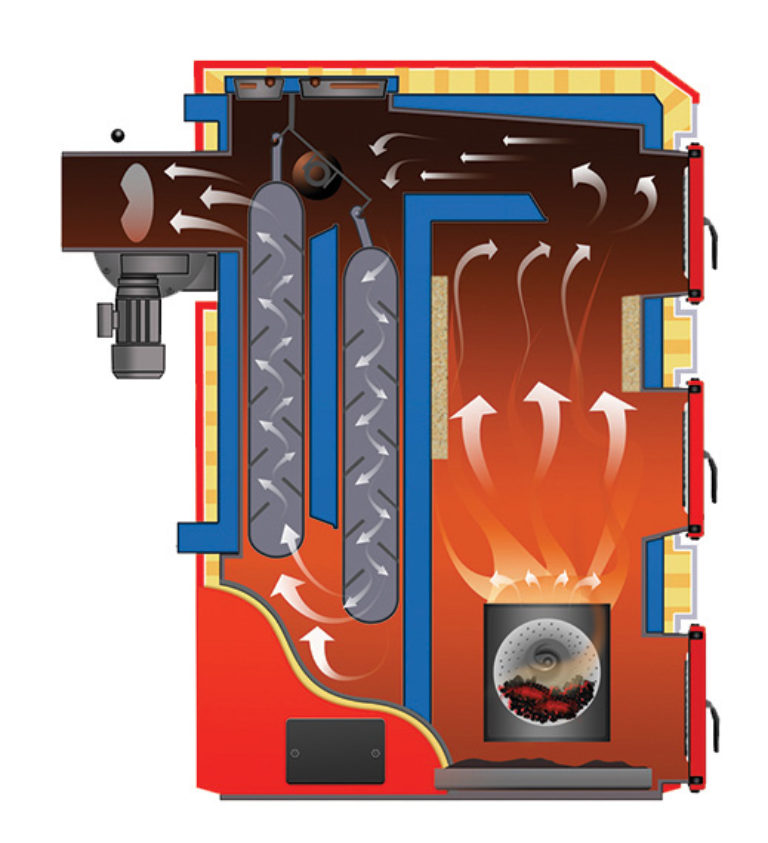

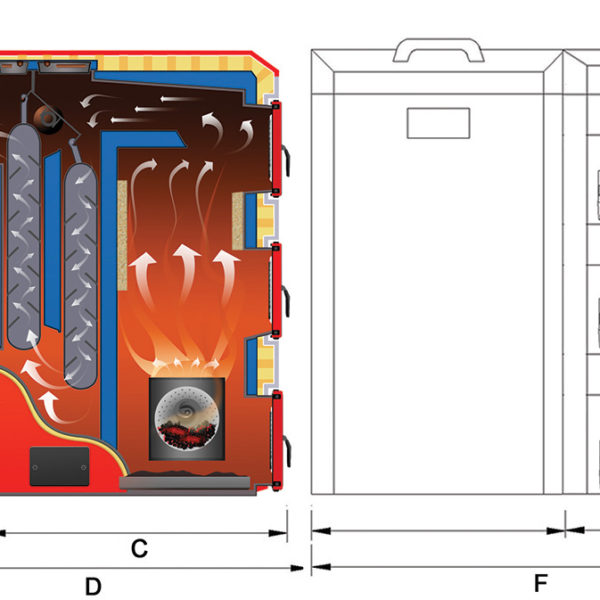

BioPellMax is an automatic boiler adapted to burn biomass in the form of pellets. The boiler body is made entirely of certified steel with a thickness of 6 mm. A significant advantage of the boiler is the plate structure of the exchanger, which has a special cleaning mechanism in the rear part. This mechanism fulfills two functions: it keeps the exchanger clean and acts as a flue gas turbulator.

Advanced automation, self-cleaning burner, controller for central heating, domestic hot water pumps, and 3 additional pumps, mixing valves, fuel ignition system and operation in modulation mode mean that the operation of this pellet boiler is reduced to the necessary minimum.

The boiler has obtained an ecological certificate from the Accredited Laboratory in Zabrze and Katowice, confirming through tests that it meets the criteria of thermal efficiency and emission requirements according to the PN-EN 303-5:2021 standard in class 5 and eco design in accordance with Commission Regulation (EU) 2015/1189 and 2009/125/EC.

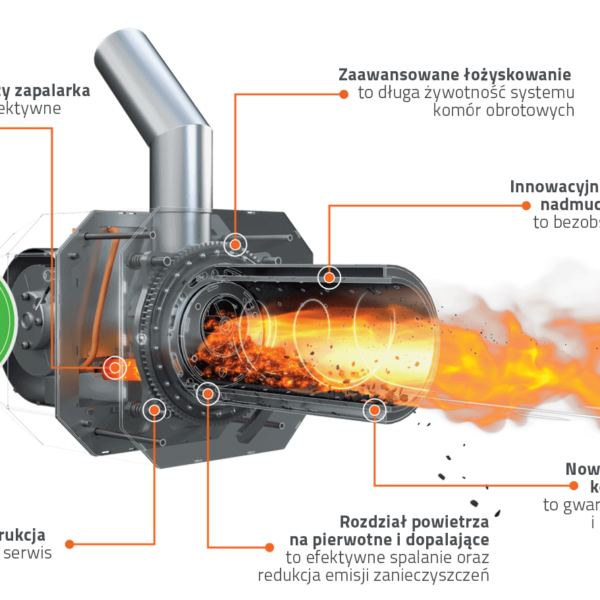

The boiler is equipped with a KIPI burner, the combustion chamber of which, by rotating, cleans the furnace from the slag and ash that has formed, or a UNI-MAX burner from Skiepko, with a segmented, step-type moving grate. Thanks to such solutions in these devices, the burners work efficiently all the time without a drop in power and do not become clogged.

These special solutions allow for smokeless combustion, low exhaust emissions and high efficiency of 91.9%.

Equipment

Standard

- Blower fan

- Advanced but functional and easy to use K902 controller

- Self-cleaning burner

Optional

- Industrial pellet tank with a capacity of 800 to 2800 liters

Characteristic

Semi-automatic smoke duct cleaning system

Innovative, rotating, self-cleaning KIPI burner

Aesthetic and functional pellet container (size depends on the boiler power)

Innovative flue gas cleaner/turbulator that increases boiler efficiency

Advanced K902 Controller

Technical data

15 20 25 32 35 45 64BioPellMax

A – Flue diameter

B – Height from bottom to bottom of flue

C – Body length

D – Total length

E – Body width

F – Width with basket at standard container

G – Height

I – Inlet sleeve

J – Return sleeve

Dimensions

15 20 25 32 35 45 64BioPellMax

Inquiry sent!

We will contact you as soon as possible.

Boiler disposal after the period of use

After the period of use, the boiler should be taken to the appropriate collection points for secondary raw materials due to the variety of materials it is made of. When dismantling the boiler, all precautions and safety measures should be observed.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.