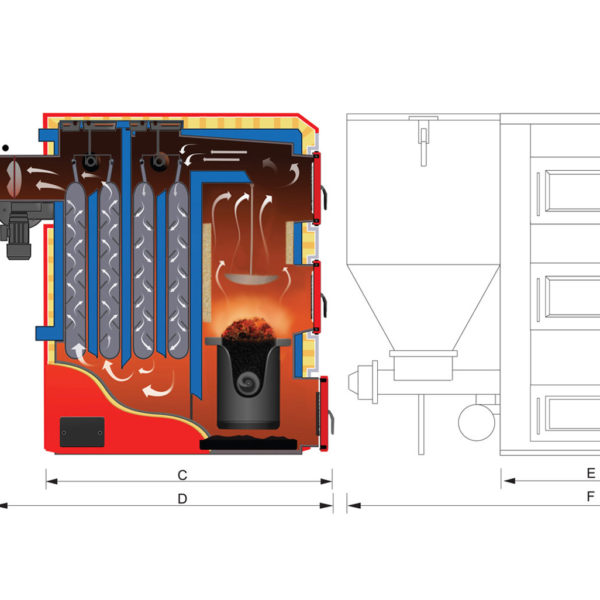

EcoMatix with a power of 75-150 kW is a boiler welded from certified sheets with a thickness of 8-10 mm. The advantage of this type of boiler is the design of the combustion chamber. This design allows for a large, accumulated surface for heat collection, which has a special cleaning mechanism at the back.

This mechanism performs two functions: it keeps the heat exchanger clean and acts as a flue gas turbulator. Thanks to this, the boiler achieves constant high efficiency. Optionally, the cleaning mechanism can be automatic, controlled and started automatically by the boiler controller.

The vertical arrangement of the flue gas channels also reduces dust deposition, while separating the flame for better use in the rear chambers.

An undeniable advantage of the boiler is the unloaded combustion chamber, i.e. the lack of cooling of the flame in the first stage of combustion allows for better combustion of carbon oxides, which has a positive effect on improving the boiler efficiency and ecology.

Innovations

A significant innovation in the boiler, improving the combustion process and reducing exhaust emissions is the patented special 3rd generation Retoscroll retort, protected by three patents, in the shape of a cone with aeration holes and protrusions creating a helical line. Another significant advantage of the boiler is the lining of the combustion chamber with ceramics in the form of special plates optimizing the combustion process. Ecomatix can operate in continuous mode, without extinguishing during the heating season. The automation allows for the preparation of hot utility water also in the summer. The boiler has obtained an ecological certificate from IChPW confirmed by tests and meets the EcoDesign standards. A single filling of the tank with fuel allows for several days of maintenance-free operation of the central heating boiler.

EcoMatix Duże Moce can operate in continuous mode, without extinguishing during the heating season. The automation allows for the preparation of hot utility water also in the summer. The boiler has obtained an ecological certificate from IChPW confirmed by tests. A single filling of the tank with fuel allows for several days of maintenance-free operation of the C.O. boiler.

Technical data

75 100 125 150 200 250 300EcoMatix High Power

A – Flue diameter

B – Height from bottom to bottom of flue

C – Body length

D – Total length

E – Width

F – Width with basket

G – Height

I – Inlet sleeve

J – Return sleeve

Dimensions

75 100 125 150 200 250 300EcoMatix High Power

Inquiry sent!

We will contact you as soon as possible.

Boiler disposal after the period of use

After the period of use, the boiler should be taken to the appropriate collection points for secondary raw materials due to the variety of materials it is made of. When dismantling the boiler, all precautions and safety measures should be observed.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.