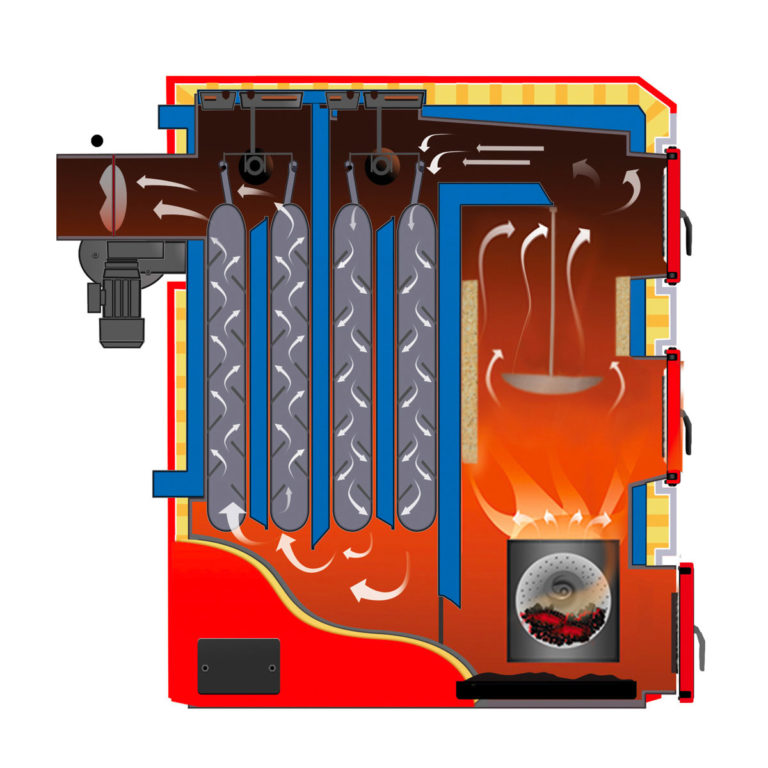

BioPellMax with power from 75-300 kW is a boiler welded from certified sheets with a thickness of 8-10 mm. The advantage of this type of boiler series is the design of the combustion chamber. This design allows for obtaining a large, cumulative heat collection surface, which has a special cleaning mechanism in the rear part.

This mechanism fulfills two functions:

it keeps the exchanger properly clean

and acts as a flue gas turbulator.

The boiler thus achieves constant, high efficiency. Optionally, the cleaning mechanism can be automatic, controlled and started automatically by the boiler controller. The vertical location of the flame tubes also limits dust settling and at the same time causes the separation of the flame for its better use in the rear chambers.

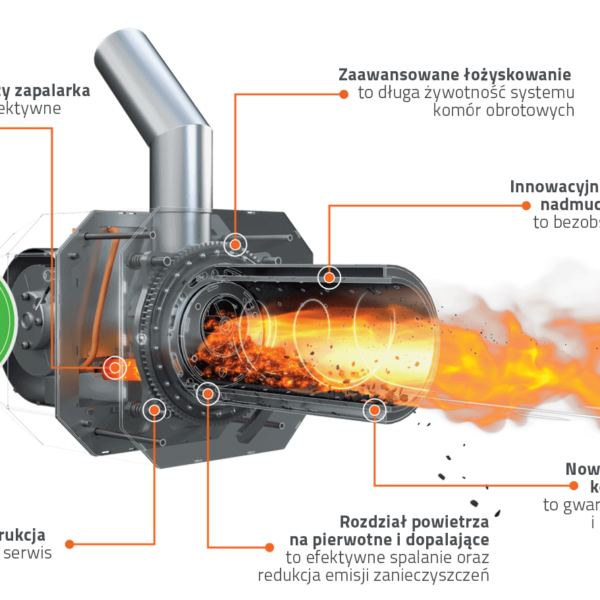

A significant advantage of the boiler is the unloaded combustion chamber, i.e. not cooling the flame in the first stage of combustion allows for better combustion of carbon oxides, which has a positive effect on improving the boiler efficiency and ecology. Another significant advantage of the boiler is the lining of the combustion chamber with ceramics in the form of special plates that optimize the combustion process. The boiler is equipped with an innovative, self-cleaning, rotary KIPI burner.

BioPellMax Duże Moce can operate in continuous mode, without extinguishing during the heating season. The automation allows for the preparation of hot utility water also in the summer.

The boiler has obtained an ecological certificate from IChPW confirmed by tests and meets the Eco Project standards. A single filling of the tank with fuel allows for several days of maintenance-free operation of the central heating boiler.

The boiler is equipped with a KIPI burner, the combustion chamber of which, by rotating, cleans the furnace from the slag and ash that has formed, or a UNI-MAX burner from Skiepko, with a segmented, step-type moving grate. Thanks to such solutions in these devices, the burners work efficiently all the time without a drop in power and do not become clogged.

These special solutions allow for smokeless combustion, low exhaust emissions and high efficiency of 91.9%.

Equipment

Standard

- Blower fan

- Advanced but functional and easy to use K900 controller

Optional

- Industrial pellet tank with a capacity of 800 to 2800 liters

Characteristic

Semi-automatic smoke duct cleaning system

Innovative, rotating, self-cleaning KIPI burner or UNI MAX step grate burner

Aesthetic and functional pellet container (size depends on the boiler power)

Innovative flue gas cleaner/turbulator that increases boiler efficiency

Advanced driver

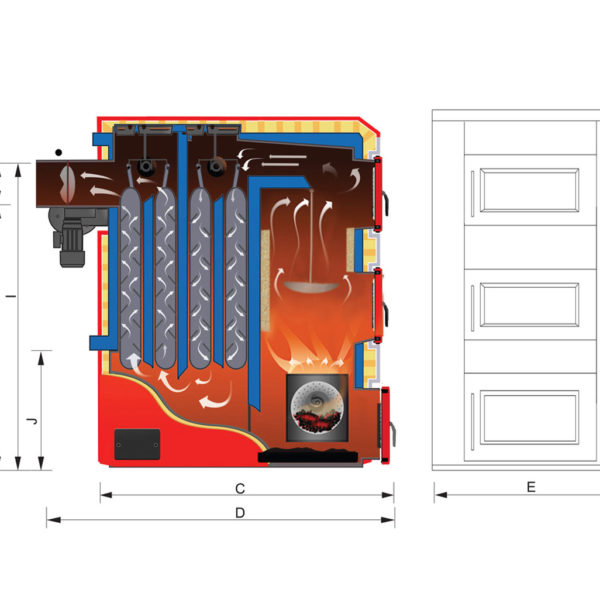

Technical data

75 100 125 150BioPellMax High Power

A – Flue diameter

B – Height from bottom to bottom of flue

C – Body length

D – Total length

E – Width

G – Height

I – Inlet sleeve

J – Return sleeve

Dimensions

75 100 125 150 300BioPellMax High Power

Inquiry sent!

We will contact you as soon as possible.

Boiler disposal after the period of use

After the period of use, the boiler should be taken to the appropriate collection points for secondary raw materials due to the variety of materials it is made of. When dismantling the boiler, all precautions and safety measures should be observed.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.