The AirKompakt heat pump was created in cooperation between our specialists and scientists from AGH University of Science and Technology in Krakow.

This device is designed and optimized specifically for use in the Polish climate. Compact dimensions, a special design based on the operation of a high-quality Copeland Scroll compressor, a large evaporator that ensures maximum heat exchange between the outside air and the working medium are just some of the parameters that make our device such an interesting proposition.

As the working medium, we used the so-called future medium in the AirKompakt pump – propane R290. It has the best thermodynamic properties among the previously used media (e.g. compared to R410), thanks to which the device is not only more energy-efficient and ecological, but also more efficient. Moreover, thanks to this medium, the AirKompakt pump does not require registration in the Central Register of Operators of Fire Protection Devices and Systems (CRO) and does not require F-gas authorizations from the installer, which significantly simplifies the process of installing the device.

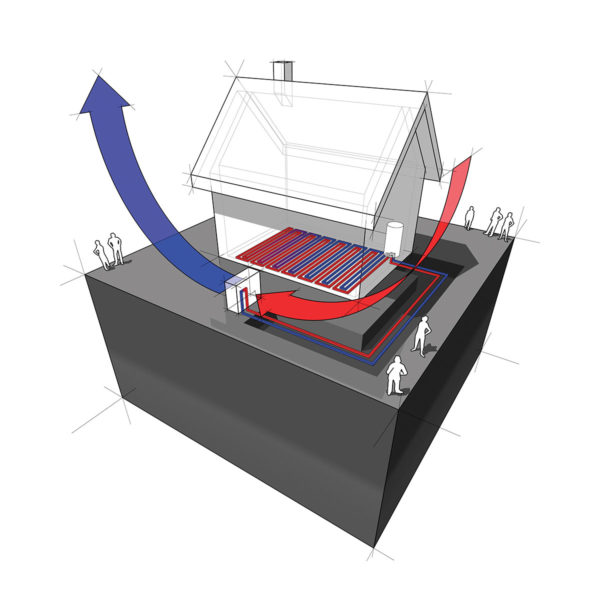

The AirKompakt pump is a device that extracts energy from the air outside the building and then transfers it to the heating system inside the building.

This is an innovative and ecological solution: there is no smoke, exhaust fumes, ash, soot or harmful substances. The device works with a compressor, so of course it requires electricity, but the consumption can be additionally reduced by connecting it to the solar collector system.

To heat the house, the AirKompakt pump, through the use of a working medium, uses natural energy circulating in the environment. Working efficiently, energy-efficiently and quietly, it does not generate pollution. To optimize the operation of our unit, we have equipped the device with the highest quality components – the use of a Power-Booster regenerative exchanger, an electric expansion valve and proprietary algorithms in the controller allowed us to obtain very good operating parameters of the machine, especially at negative air temperatures.

The AirKompakt air heat pump was manufactured in the mountains and was designed to work in a mountain climate. The device is characterized by higher COP efficiency coefficients compared to similar devices powered by synthetic refrigerants – even at negative temperatures. Our unit has been thoroughly tested for operation in unfavorable weather conditions. Here are its most important parameters!

- Pump operation down to -25°C!

- High COP (even above 5.0) due to good physical and chemical properties of the working medium

- Supply temperature – over 65°C

- Production in Poland – product development in cooperation with AGH in Krakow, production in a company with Polish capital and many years of tradition

- Components from renowned European manufacturers

- Night mode, during which the pump can be silenced

- No need to register the pump in the Central

- Register of Operators

- Teleservice via the Internet (online service)

- Modern and environmentally friendly design – guarantee of many years of failure-free operation

- Possibility of cascade operation of up to 6 devices

- Modern and aesthetic design of the device

- COP indicators at external temperatures from -7 to -25°C even 20–40% higher compared to other products of this type

- Special acoustic insulation of the unit chamber, double compressor suspension, and a quiet fan with smooth speed control and blades in the shape of “owl feathers” minimize noise

- Electronic expansion valve guaranteeing maximum efficiency of the pump operating at different temperatures

- Heat recovery from the heated evaporator after defrosting, which automatically translates into lower energy consumption throughout the year

- Power-booster – an economizer that enhances the pump’s COP indicators at low outside temperatures

- Soft-Start – a soft start system designed to reduce the consumption of starting current that extends the compressor’s operation

- PWM circulation pump with smooth performance regulation

- Control of evaporator frosting and defrosting function if necessary – saving electricity

- Implementation of defrosting mode without switching off the compressor – increasing the

- COP coefficient and the service life of the device

- Control with a modern and dedicated algorithm – innovative design

- Pump operation function in the summer as air conditioning

- Placement outside the building – saving space in the boiler room.

Energy class A++

Energy factor R290 Propane

Support for the AGH University of Science and Technology in Krakow

Triple action – central heating, domestic hot water and cooling

COP values at outdoor temperatures from -7°C to -25°C are up to 20-40% higher than other products of this type.

- Special acoustic insulation of the unit chamber, double compressor suspension, and a quiet fan with smooth speed control and owl-feather-shaped blades minimize noise

- Electronic expansion valve guarantees maximum pump efficiency at different temperatures

- Heat recovery from the heated evaporator after defrosting, which automatically translates into lower energy consumption throughout the year

- Power-booster – economizer that increases the pump’s COP at low outside temperatures

- Soft-Start – a soft start system, the purpose of which is to reduce the starting current that extends the compressor’s operation

- PWM circulation pump with smooth performance regulation

- Evaporator frost control and defrosting if necessary – saving electricity

- Implementation of defrosting mode without switching off the compressor – increasing the COP coefficient and the service life of the device

- Control with a modern and dedicated algorithm – innovative design

Pump operation function during - Pump operation function in summer as air conditioning

- Placement outside the building – saving space in the boiler room

Components used in the AIRKOMPAKT heat pump

To optimize the operation of our unit in various weather conditions, we have equipped it with the highest quality components. Here are the components that have been used in the AirKompakt heat pump.

The fan used in the AirKompakt heat pump, despite its large size, does not generate excessive noise.

This is possible thanks to the shape of owl feathers and smooth speed control, as well as special acoustic insulation of the generator chamber and double compressor suspension.

Power Booster

The Power Booster regenerative exchanger used in the AirKompakt pump fulfils two basic functions: it increases the COP index and pump power at low temperatures ranging from -15 to -28°C, and also fully protects the compressor against flooding with the agent and allows the pump to switch from operating mode to defrosting mode and vice versa.

The plate condenser manufactured by the Swedish company SWEP hits the mark: the module has a large heat exchange surface and is selected as standard to work in cooling mode; the pump has an algorithm as standard that allows the device to work as an air conditioner.

The soft start module, which is standard equipment of the AirKompakt heat pump, enables smooth start-up of the machine, thanks to which the unit does not burden the home’s electrical network; it also protects the compressor itself.

The fins used in our unit have been designed so that the droplets do not come into contact with the two walls of the exchanger.

Thanks to this design, the device consumes less energy necessary for the defrosting process, as a result the entire process is faster. The time between subsequent defrosting cycles is on average from 2.5 to 4 hours and does not affect the efficiency and power of the device.

The evaporator built into the device has a very large heat exchange surface – it was designed to work in the climate conditions of Central Europe, especially the climate of Poland and the demanding mountain climate.

The brain of the automation in the AirKompakt pump is a controller from a Polish manufacturer – TECH. The controller is equipped with proprietary algorithms designed in cooperation with scientists from AGH (including defrosting algorithms, an algorithm for switching on additional heat sources, an algorithm for performing heating functions according to the heating curve, readings of electrical or thermal energy).

Additionally, the controller is equipped with a web application, thanks to which we have constant remote access to the heat pump (possibility of performing e-service).

Emerson is a leading compressor manufacturer in the world, and its products are among the best available on the market. The Copeland Scroll compressor used in the AirKompakt pump is a machine designed to work with the R290 refrigerant.

Its most important features are:

- thermal protection of the discharge temperature

- axial and radial compliance – ensures good contact of the spirals during operation, which results in long-term tightness, if liquid gets between them, it allows the spirals to separate

- having a safety valve.

Selecting a heat pump housing

When choosing an AirKompakt heat pump, you are not only choosing good technical parameters, but also a qualitative, minimalist design and the ability to match the device’s casing to the decor of your home. All the covers we offer are made of a material resistant to changing weather conditions. This is the choice you face!

This is definitely the most classic casing of our heat pump. The gray-silver base (RAL 9006 palette) with accents of dynamic red is a standard option for which you do not have to pay extra. It is distinguished by a universal design that fits into most building facades.

The Tatra Design casing is distinguished primarily by its direct reference to the highlander style. It is made of weather-resistant sheet metal, but imitates the color and structure of wood. The fan head itself can be finished in the shape of a traditional rosette, as well as in the standard version.

The Modern Design casing is definitely the most modern version of the heat pump cover. It stands out not only with its interesting, minimalist design and contrasting colors, but also with the material it was made of. Dibond is a light and durable material, resistant to all weather conditions.

Product benefits

The hybrid heating system is the implementation of a project that enables the combination of building heating economy and ecological issues.

This is a simple way to heat a single-family home and prepare domestic hot water for the whole family. What does it involve? The basic source of heat in this system is an ecological heat pump.

However, in appropriate conditions, it can be supported by an electric heater, an oil or pellet boiler or finally solar collectors. As a user of such a system, do you have to constantly monitor all parameters and modulate the proportions of the devices’ operation? Nothing like that.

The advanced control algorithm makes the heat pump decide when it is worth switching on an additional energy source – the primary goal is to automatically optimize the operation of the system in such a way that heating is as economical as possible.

To further reduce the maintenance costs of the installation, you can decide to combine the heat pump with a set of photovoltaic panels, which will fully meet the consumption of electricity needed to operate the heat pump, as a result of which your heating will be practically free.

Such as high-quality components and efficient and ecological solutions!

Why AirKompakt heat pump?

The AirKompakt heat pump stands out from the competition in many ways. It is enough to mention the highest quality components and efficient and ecological solutions that we use in our activities with full awareness. Choosing our AirKompakt unit is not only choosing a modern device that will provide you and your loved ones with thermal comfort for many years, but also constant cooperation with a team of experienced Kołton specialists, who are at your disposal both in the sphere of choosing the device, as well as its daily use and servicing. What distinguishes our AirKompakt heat pump?

- Copeland compressor adapted to work with R290 propane refrigerant

- Durable heat exchanger made of high-quality stainless steel

- High COP even above 5.0 due to good physical and chemical properties of the working medium

- Lower discharge pressure results in lower energy consumption, lower noise and longer compressor durability

- Built-in phase sequence and loss sensor

- Meter of electricity consumed by the device

- Meter of thermal energy, device power and COP available in the web application

- Possibility of automatic cooperation with an additional heat source: electric heater, pellet boiler, gas or oil boiler

- Uncomplicated installation of the entire unit outside the building – no need to run a gas route inside the building, no drilling. Multi-stage protection against freezing of the water part outside the building

- RES – full use of renewable raw materials

- The most ecological way of heating CO/DHW

- Possibility of expanding the protection with UPS (for areas with long and frequent periods of power outages)

- TECH controller with intuitive menu, with the possibility of control via the Internet or using an application on a mobile device

- Heat recovery from the heated evaporator after defrosting – lower average annual energy consumption

- Possibility of using the device in single-family houses, service and public utility buildings

KOŁTON Air/water heat pump AirKompakt

1:20Inquiry sent!

We will contact you as soon as possible.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.