Compact and economical wood gasification furnace – Trotex

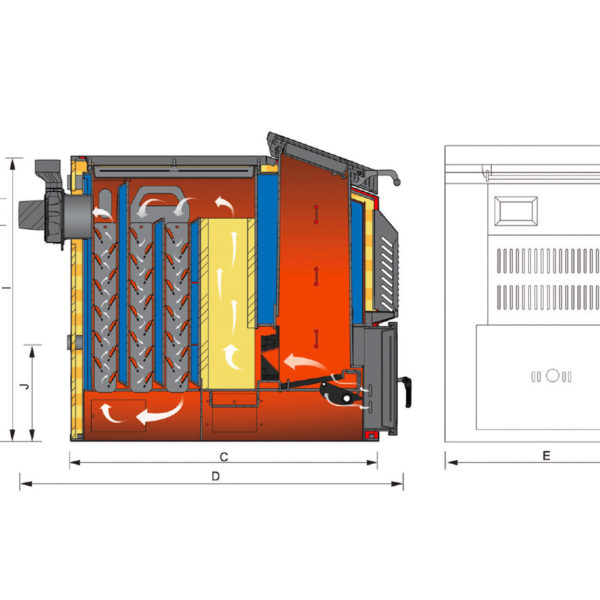

The Trotex boiler is a device designed for burning piece wood using the gasification method (bottom combustion). The individual elements of the boiler are made of 6–10 mm thick sheets, which translates not only into work efficiency, but also safety and comfort of use. The Trotex wood gasification furnace is simple and trouble-free in everyday use. The device is equipped with an electronic temperature controller, which allows you to control the operation of the exhaust fan and thus control the operating temperature of the boiler. The loading door of the furnace is supported by a gas actuator, and the boiler feed has been designed in such a way as to facilitate loading larger pieces of wood. Smoking when the loading flap is opened is prevented by the exhaust fan and the limit switch.

Equipment

Standard

- Exhaust fan

- ST 891 controller for a hopper boiler (fan, central heating and domestic hot water pumps, floor and mixing valve operation)

Characteristic

Large firebox for piece wood

Easy access to the exchanger for easy cleaning

Sheet thickness from 6-10 mm

Technical data

35Trotex

A – Flue diameter

B – Height from bottom to bottom of flue

D – Total length

E – Width

H – Total height

I – Inlet sleeve

J – Return sleeve

Dimensions

35Trotex

Inquiry sent!

We will contact you as soon as possible.

Boiler disposal after the period of use

After the period of use, the boiler should be taken to the appropriate collection points for secondary raw materials due to the variety of materials it is made of. When dismantling the boiler, all precautions and safety measures should be observed.

How does a wood gasification boiler work?

The wood gasification method is one of the most effective ways of burning it. Here’s how a wood gasification boiler works: solid fuel is heated, and as a result of the process, flammable wood gas is created – the so-called holzgas, which passes to the lower part of the boiler through a layer of embers and is burned in the combustion chamber nozzle as a result of mixing with oxygen. The wood gasification furnace therefore uses the phenomenon of pyrolysis, i.e. combustion of gases created as a result of burning wood with a deficiency of oxygen, and the final effect is the creation of thermal energy. The process taking place in all wood gasification boilers can be divided into 4 stages:

I – drying and gasification of wood

II – initial combustion of wood gas

III – post-combustion of wood gas and collection of heat energy from exhaust gases

IV – ejection of cooled exhaust gases through the chimney.

What can be burned in a wood gasification furnace?

A wood gasification boiler is a device that can be powered by piece wood, as well as chips, sawdust and briquettes. Importantly, both deciduous and coniferous wood will work well here. Advanced technology and impressive technical parameters of this device mean that the wood gas combustion process is equally effective with both types of fuel, providing more heat and generating less pollution.

Advantages of a wood gasification furnace

The technology used in wood gasification boilers makes these devices a great alternative to pellet, eco-pea coal and other fossil fuel furnaces. These compact and convenient in everyday use boilers can be used to heat your home, as well as prepare hot utility water. Here are the most important advantages of wood gasification boilers!

High efficiency of the device

In the process of wood gasification, the vast majority of fuel is converted into heat energy, which means very high boiler efficiency, which in turn means lower fuel costs (it is worth remembering about the appropriate fuel moisture, which should not exceed 15–20%).

Even lower exhaust emissions

The wood gasification process is associated with low emissions of harmful compounds into the atmosphere. Pyrolytic combustion of wood is one of the cleanest ways of obtaining heat energy from solid fuel.

Savings on heating

First of all, wood is still one of the cheapest types of fuel, and the economy of the wood gasification process allows you to obtain more heat energy from the same amount of fuel than with standard wood combustion.

Convenience and cleanliness of operation

Trotex is a compact device that has been designed with user convenience in mind: an electronic temperature controller, a gas actuator on the door, an exhaust fan and similar amenities make the device safe, simple and clean to use.

Possibility of obtaining funding

Our wood gasification boiler meets the EcoDesign and class 5 standards, which means that you can receive funding from one of several support programs for the purchase of this device.

Can you get a subsidy for a wood gasification boiler?

Absolutely! A wood gasification furnace is a modern device that fits perfectly into the nationwide program to combat smog and promote ecological sources of heating. It is therefore worth familiarizing yourself with local support programs and trying to get the highest possible subsidy for the purchase of a gasification wood furnace.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.