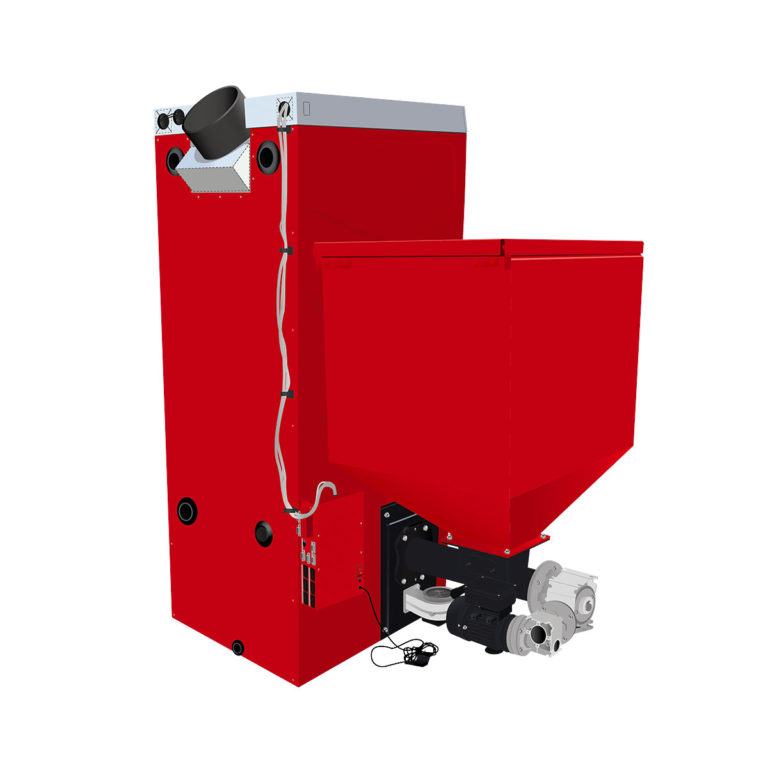

The Duox 5th class boiler for eco-pea coal is a safe, energy-saving and environmentally friendly product. Duox and Duox ZX with the eco design certificate is a heating boiler with an installed tank and automatic fuel feeder adapted to burn eco-pea coal. The boiler body is made entirely of certified sheet metal with a thickness of 6-8 mm.

The Duox 5th Class boiler with a feeder, thanks to the modern technology used in its production, guarantees:

– safety of use

– low exhaust emissions;

– high efficiency – from 91.8% ÷ 93.7%.

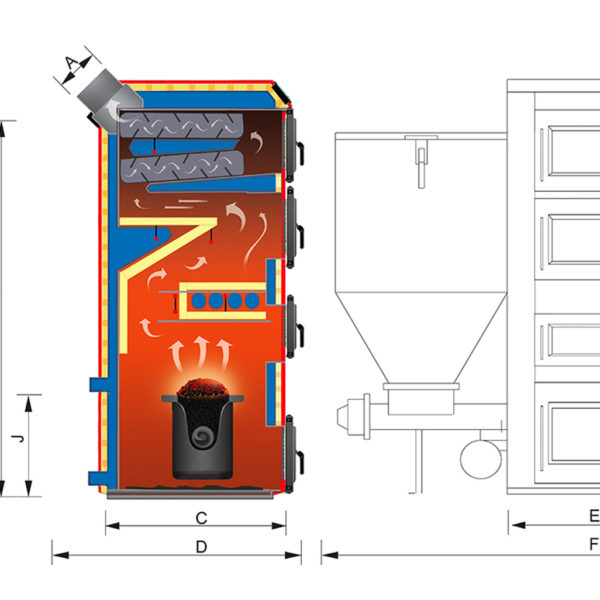

High efficiency is achieved with the help of exhaust swirlers in the horizontal structure of the exchanger, which act as a turbulator. The tubular exchanger cools the refractory plates, thus extending their service life and reducing the emission of harmful compounds generated during combustion. The advanced furnace controller continuously monitors the water temperature in the heating boiler and manages the operation of the mixing valve actuator, heat pump, fan and feeder. It also works with various types of room thermostats and Internet communication modules. The boiler has a vertical flue outlet design only. The third generation Retoscroll retort, protected by three patents, improves the combustion process.

Class 5 eco-pea coal boilers with ecodesign certificate – with cast iron feeder, power 12, 20 and 25 kW

We sell Duox ZX class 5 eco-pea coal boilers with a power of 12; 20 and 25 kW. The Duox ZX class 5 boiler is available in a version with a cast iron feeder from Ekoenergia.

The main advantages of Duox boilers include:

– heating domestic hot water without the need to heat the central heating system – thanks to the “summer mode” function;

– the existence of a combustion process optimization function thanks to special ceramic plates;

– possibility of continuous operation – also during the heating season;

– maintenance-free operation for several days after a single filling of the eco-pea coal container.

The boiler of our production, both with the RETOSCROLL furnace and the cast iron feeder, has obtained the IChPW ecological certificate confirmed by tests and meets the requirements of Ecodesign. We encourage you to make purchases and contact us to obtain detailed information about these and our other products.

Technical data

12 19 25 35Duox

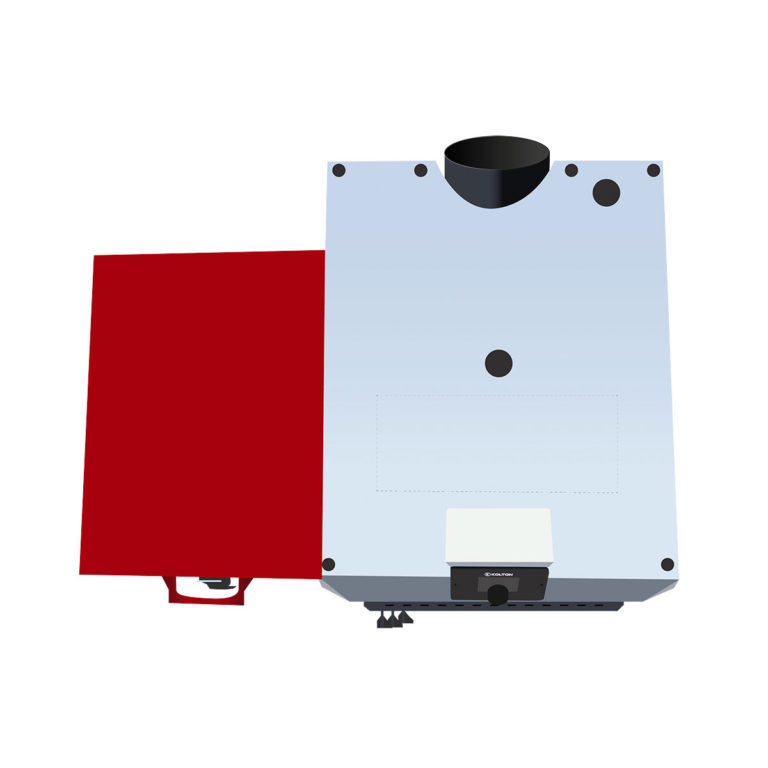

A – Flue diameter

B – Height from bottom to bottom of flue

C – Body length

D – Total length

E – Width

F – Width with basket

G – Height

I – Inlet sleeve

J – Return sleeve

Dimensions

12 19 25 35Duox

KOŁTON Eco-pea coal boilers class 5

Inquiry sent!

We will contact you as soon as possible.

Boiler disposal after the period of use

After the period of use, the boiler should be taken to the appropriate collection points for secondary raw materials due to the variety of materials it is made of. When dismantling the boiler, all precautions and safety measures should be observed.

You don’t know how to choose the right solution?

Specify your needs and we will choose a solution for your investment.